RoHS & MOTM (UPDATED June 3rd)

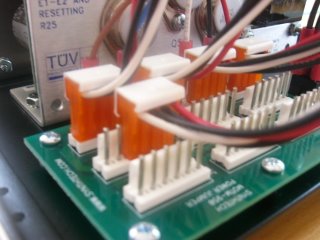

RoHS is a new European legislation aimed ad banning harmfull substances (lead, mercury etc) in electronic products, as of july 1st 2006. See http://www.rohs.gov.uk/

Currently , all kits by Synthesis Technolgy come with solder by Kester, and is currently not RoHS compliant.

In order to continue shipping kits, Synthesis Technology will ship it's kits to the EU without solder, unless it can find RoHS compliant solder to use.

Solder is available in many qualities, and the solder used so far, is very reliable, and lasts a long time, a reason why it was used.

The assembled modules are currently made with the same solder, and if Synthesis Technology cannot find a suitable solder it will be forced to stop shipping assembled modules to the EU. Hopefully a better solution will be found (research into wave soldering is done) which will be good, but mayl raise the price for assembled modules.

Currently I am researching replacements for the Kester solder types needed here in the EU, as soon as I know of good solutions, then I will post it here.

UPDATE:

Kester types and their part numbers recommended by Synthesis Technology are.

For 331 (the organic flux type)

24-6337-6401

For 245: (the No Clean type)

24-6337-8800

However I have not found a EU supplier for these parts yet.